Grafit éléktroda nipples 3tpi 4tpi Nyambungkeun Pin T3l T4l

Katerangan

Nipple éléktroda grafit nyaéta bagian leutik tapi penting dina prosés pembuatan baja EAF. Ieu mangrupakeun komponén cylindrical ngawangun nu nyambungkeun éléktroda ka tungku. Salila prosés steelmaking, éléktroda ieu lowered kana tungku jeung disimpen dina kontak jeung logam molten. Arus listrik ngalir ngaliwatan éléktroda, ngahasilkeun panas, nu melts logam dina tungku. Nipple muterkeun hiji peran krusial dina ngajaga sambungan listrik stabil antara éléktroda jeung tungku.

Parameter Téknis

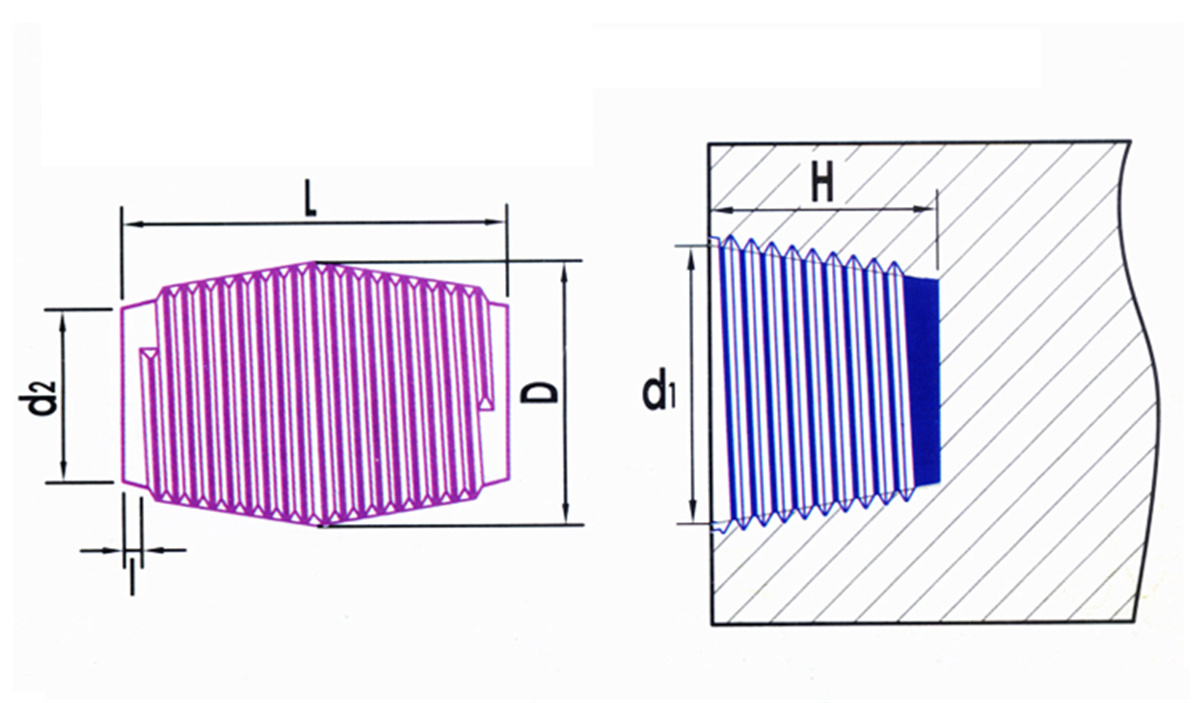

Gufan Carbon Conical Nipple sareng Socket Drawing

| Diaméterna nominal | Kodeu IEC | Ukuran Nipple (mm) | Ukuran Socket (mm) | Pitch | |||||

| mm | inci | D | L | d2 | I | d1 | H | mm | |

| Toleransi (-0.5~0) | Toleransi (-1~0) | Toleransi (-5~0) | Toleransi (0~ 0.5) | Toleransi (0~7) | |||||

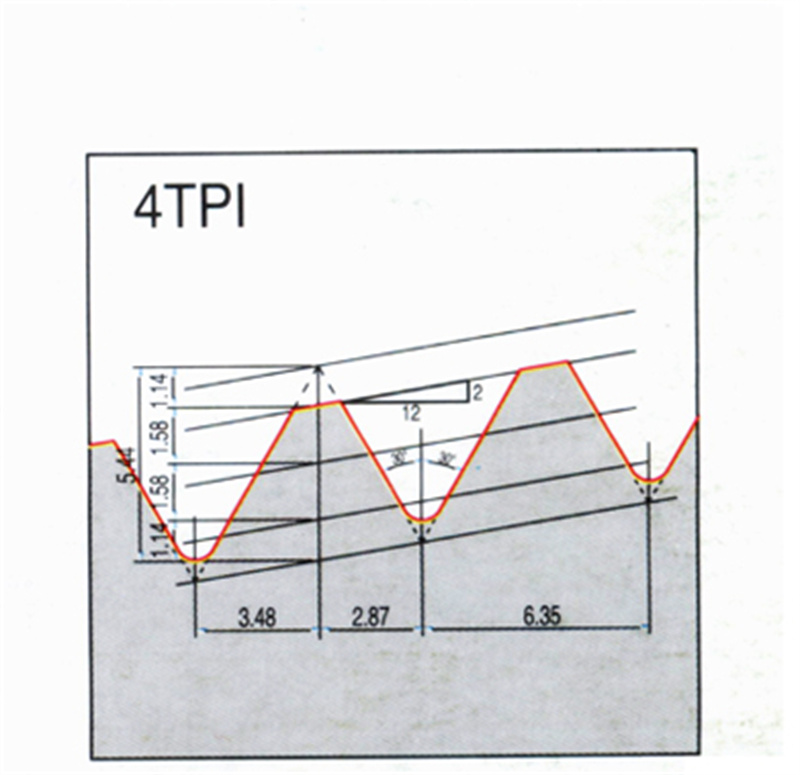

| 200 | 8 | 122T4N | 122.24 | 177.80 | 80.00 | <7 | 115.92 | 94.90 | 6.35 |

| 250 | 10 | 152T4N | 152.40 | 190.50 | 108.00 | 146.08 | 101.30 | ||

| 300 | 12 | 177T4N | 177.80 | 215.90 | 129.20 | 171.48 | 114.00 | ||

| 350 | 14 | 203T4N | 203.20 | 254.00 | 148.20 | 196.88 | 133.00 | ||

| 400 | 16 | 222T4N | 222.25 | 304.80 | 158.80 | 215.93 | 158.40 | ||

| 400 | 16 | 222T4L | 222.25 | 355.60 | 150.00 | 215.93 | 183.80 | ||

| 450 | 18 | 241T4N | 241.30 | 304.80 | 177.90 | 234.98 | 158.40 | ||

| 450 | 18 | 241T4L | 241.30 | 355.60 | 169.42 | 234.98 | 183.80 | ||

| 500 | 20 | 269T4N | 269.88 | 355.60 | 198.00 | 263.56 | 183.80 | ||

| 500 | 20 | 269T4L | 269.88 | 457.20 | 181.08 | 263.56 | 234.60 | ||

| 550 | 22 | 298T4N | 298.45 | 355.60 | 226.58 | 292.13 | 183.80 | ||

| 550 | 22 | 298T4L | 298.45 | 457.20 | 209.65 | 292.13 | 234.60 | ||

| 600 | 24 | 317T4N | 317,50 | 355.60 | 245.63 | 311.18 | 183.80 | ||

| 600 | 24 | 317T4L | 317,50 | 457.20 | 228.70 | 311.18 | 234.60 | ||

| 650 | 26 | 355T4N | 355.60 | 457.20 | 266.79 | 349.28 | 234.60 | ||

| 650 | 26 | 355T4L | 355.60 | 558.80 | 249.66 | 349.28 | 285.40 | ||

| 700 | 28 | 374T4N | 374.65 | 457.20 | 285.84 | 368.33 | 234.60 | ||

| 700 | 28 | 374T4L | 374.65 | 558.80 | 268.91 | 368.33 | 285.40 | ||

| Diaméterna nominal | Kodeu IEC | Ukuran Nipple (mm) | Ukuran Socket (mm) | Pitch | |||||

| mm | inci | D | L | d2 | I | d1 | H | mm | |

| Toleransi (-0.5~0) | Toleransi (-1~0) | Toleransi (-5~0) | Toleransi (0~ 0.5) | Toleransi (0~7) | |||||

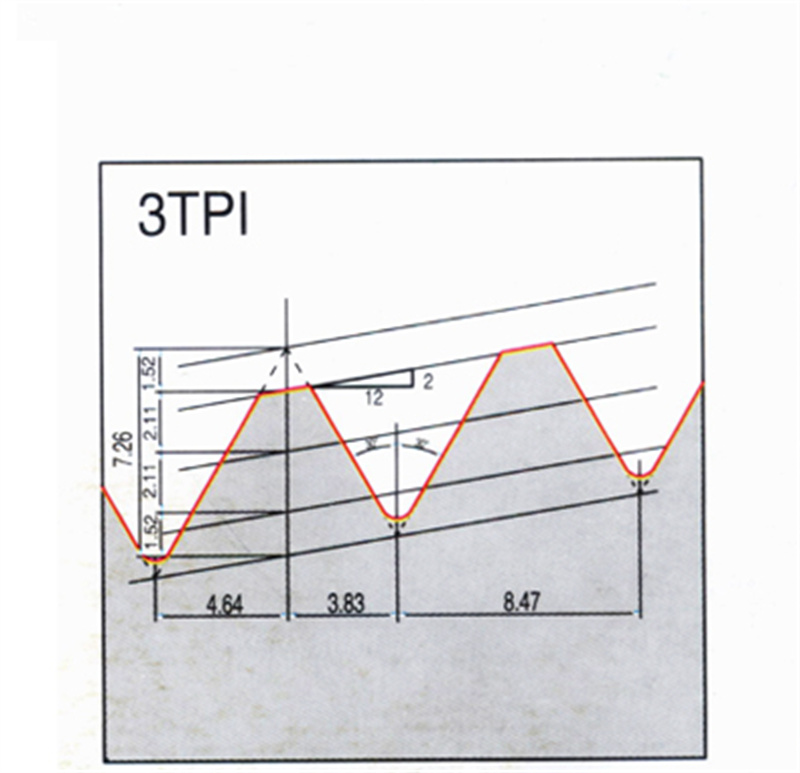

| 250 | 10 | 155T3N | 155.57 | 220.00 | 103.80 | <7 | 147.14 | 116.00 | 8.47 |

| 300 | 12 | 177T3N | 177.16 | 270.90 | 116.90 | 168.73 | 141.50 | ||

| 350 | 14 | 215T3N | 215.90 | 304.80 | 150.00 | 207.47 | 158.40 | ||

| 400 | 16 | 241T3N | 241.30 | 338.70 | 169.80 | 232.87 | 175.30 | ||

| 450 | 18 | 273T3N | 273.05 | 355.60 | 198.70 | 264.62 | 183.80 | ||

| 500 | 20 | 298T3N | 298.45 | 372.60 | 221.30 | 290.02 | 192.20 | ||

| 550 | 22 | 298T3N | 298.45 | 372.60 | 221.30 | 290.02 | 192.20 | ||

| Éléktroda | Baku Beurat Nipples | ||||||||

| Ukuran éléktroda nominal | 3TPI | 4TPI | |||||||

| Diaméter × Panjang | T3N | T3L | T4N | T4L | |||||

| inci | mm | lbs | kg | lbs | kg | lbs | kg | lbs | kg |

| 14 × 72 | 350 × 1800 | 32 | 14.5 | - | - | 24.3 | 11 | - | - |

| 16 × 72 | 400 × 1800 | 45.2 | 20.5 | 46.3 | 21 | 35.3 | 16 | 39.7 | 18 |

| 16 × 96 | 400 × 2400 | 45.2 | 20.5 | 46.3 | 21 | 35.3 | 16 | 39.7 | 18 |

| 18 × 72 | 450 × 1800 | 62.8 | 28.5 | 75 | 34 | 41.9 | 19 | 48.5 | 22 |

| 18 × 96 | 450 × 2400 | 62.8 | 28.5 | 75 | 34 | 41.9 | 19 | 48.5 | 22 |

| 20 × 72 | 500 × 1800 | 79.4 | 36 | 93.7 | 42.5 | 61.7 | 28 | 75 | 34 |

| 20 × 84 | 500 × 2100 | 79.4 | 36 | 93.7 | 42.5 | 61.7 | 28 | 75 | 34 |

| 20 × 96 | 500 × 2400 | 79.4 | 36 | 93.7 | 42.5 | 61.7 | 28 | 75 | 34 |

| 20 × 110 | 500 × 2700 | 79.4 | 36 | 93.7 | 42.5 | 61.7 | 28 | 75 | 34 |

| 22 × 84 | 550 × 2100 | - | - | - | - | 73.4 | 33.3 | 94.8 | 43 |

| 22 × 96 | 550 × 2400 | - | - | - | - | 73.4 | 33.3 | 94.8 | 43 |

| 24 × 84 | 600 × 2100 | - | - | - | - | 88.2 | 40 | 110.2 | 50 |

| 24 × 96 | 600 × 2400 | - | - | - | - | 88.2 | 40 | 110.2 | 50 |

| 24 × 110 | 600 × 2700 | - | - | - | - | 88.2 | 40 | 110.2 | 50 |

| Diaméter éléktroda | inci | 8 | 9 | 10 | 12 | 14 |

| mm | 200 | 225 | 250 | 300 | 350 | |

| Momen Easing | N·m | 200–260 | 300–340 | 400–450 | 550–650 | 800–950 |

| Diaméter éléktroda | inci | 16 | 18 | 20 | 22 | 24 |

| mm | 400 | 450 | 500 | 550 | 600 | |

| Momen Easing | N·m | 900–1100 | 1100–1400 | 1500–2000 | 1900–2500 | 2400–3000 |

Parentah instalasi

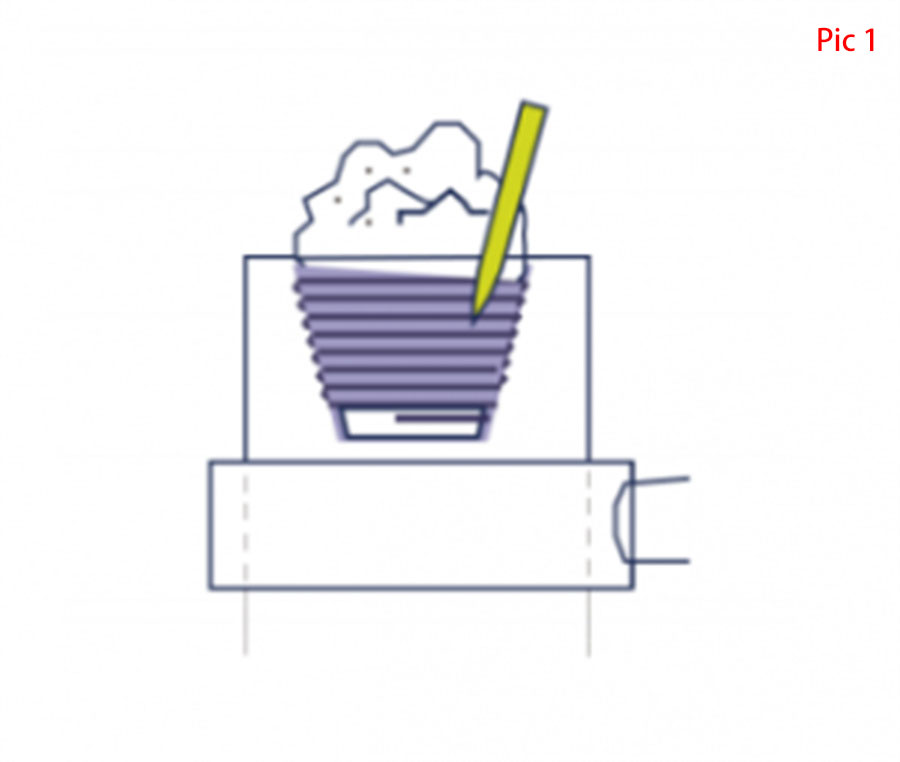

- Sateuacan masang nipple éléktroda grafit, Bersih lebu jeung kokotor dina beungeut cai jeung stop kontak éléktroda jeung nipple kalawan hawa dikomprés; (tingali pic1)

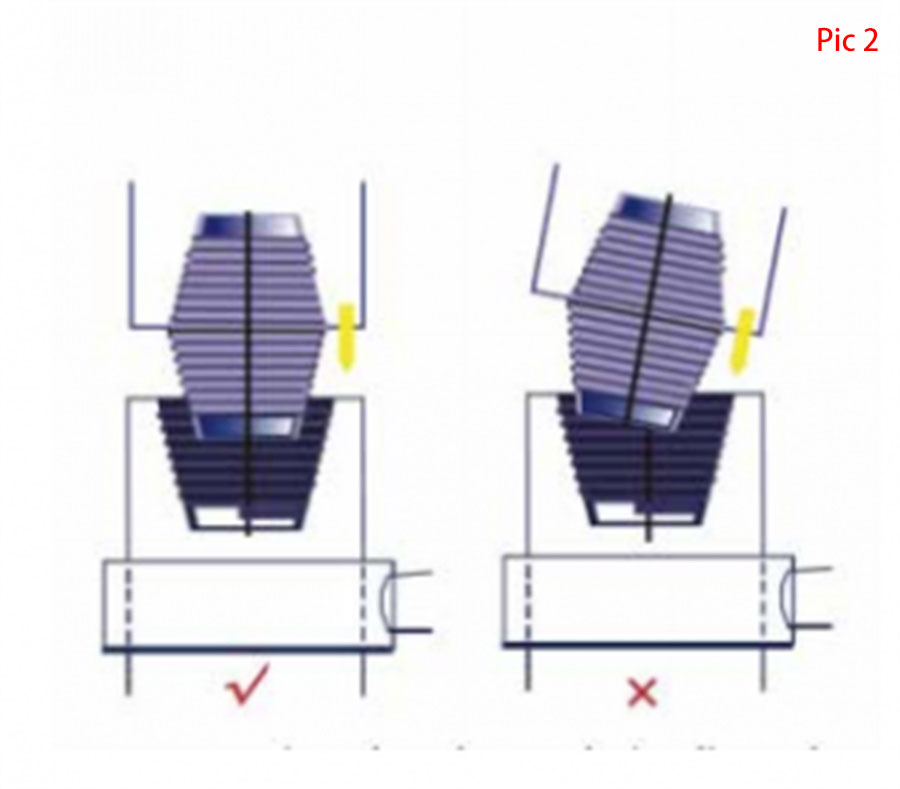

- Garis tengah grafit éléktroda nipple kudu dijaga konsisten salila dua lembar éléktroda grafit gabungan babarengan; (tingali pic2)

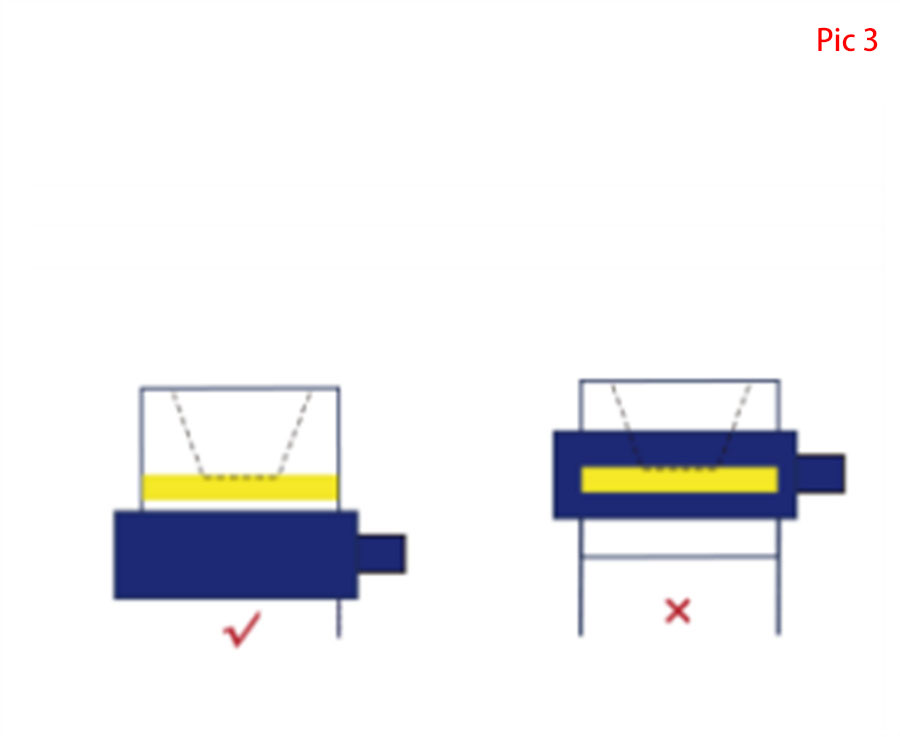

- clamper éléktroda kudu nahan dina posisi ditangtoskeun: luar garis kaamanan tungtung luhur; (tingali pic3)

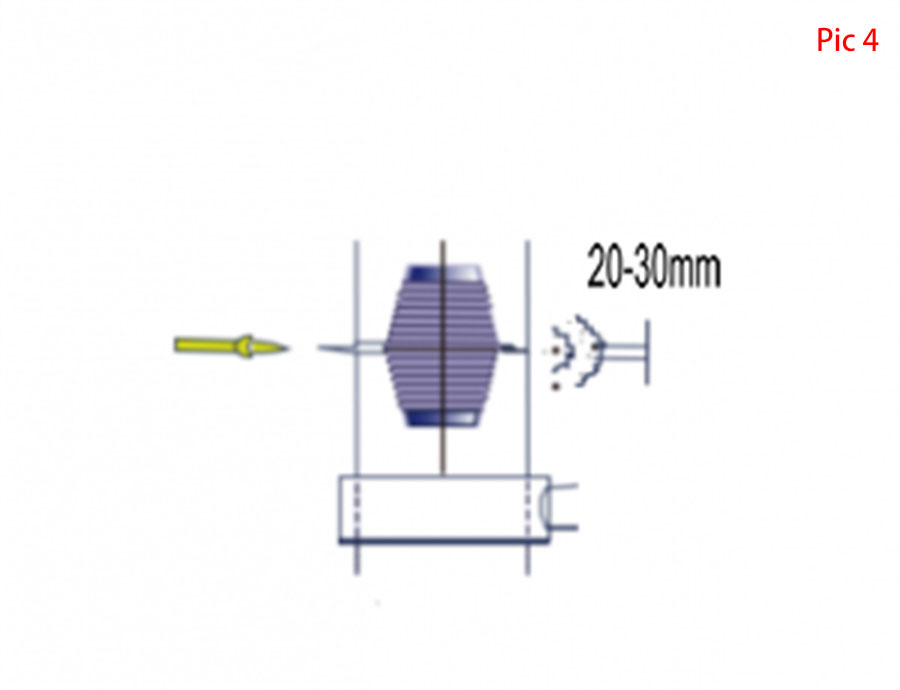

- Sateuacan tightening nipple, pastikeun beungeut nipple beresih tanpa lebu atawa kotor. (tingali pic4)

Nipple éléktroda grafit mangrupakeun komponén kritis dina prosés steelmaking EAF. Kualitas na langsung mangaruhan efisiensi sareng reliabilitas prosés. Ngagunakeun nipples kualitas luhur penting pikeun nyegah kacilakaan éléktroda sarta mastikeun prosés steelmaking lemes jeung produktif. Numutkeun data industri, leuwih 80% tina kacilakaan éléktroda disababkeun ku nipples rusak jeung tripping leupas. Pikeun milih nipple anu leres, faktor di handap ieu kedah dipertimbangkeun.

- konduktivitas termal

- Résistivitas listrik

- Kapadetan

- Kakuatan mékanis

Nalika milih nipple éléktroda grafit, penting pikeun mertimbangkeun kualitas, ukuran, sareng bentukna, sareng kasaluyuan sareng spésifikasi éléktroda sareng tungku. Ku milih nipple katuhu, pabrik bisa ningkatkeun kualitas baja maranéhanana sarta ngurangan waragad pakait sareng downtime sarta produktivitas goréng.

Kaasup konduktivitas termal, résistansi listrik, dénsitas, sareng kakuatan mékanis.