Kapadetan Tinggi Diaméter Leutik Tungku grafit éléktroda Pikeun Ladle Tungku Blast Tungku Dina Lebur Baja

Parameter Téknis

Bagan 1: Parameter Téknis Pikeun Éléktroda Grafit Diaméter Leutik

| diaméterna | Bagian | Résistansi | Kakuatan Flexural | Modulus ngora | Kapadetan | CTE | Abong | |

| Inci | mm | μΩ·m | MPa | GPa | g/cm3 | ×10-6/ ℃ | % | |

| 3 | 75 | Éléktroda | 7.5-8.5 | ≥9.0 | ≤9.3 | 1.55-1.64 | ≤2.4 | ≤0.3 |

| Puting | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 4 | 100 | Éléktroda | 7.5-8.5 | ≥9.0 | ≤9.3 | 1.55-1.64 | ≤2.4 | ≤0.3 |

| Puting | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 6 | 150 | Éléktroda | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Puting | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 8 | 200 | Éléktroda | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Puting | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 9 | 225 | Éléktroda | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Puting | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 10 | 250 | Éléktroda | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Puting | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

Bagan 2: Kamampuh Mawa Ayeuna Pikeun Éléktroda Grafit Diaméter Leutik

| diaméterna | Beban ayeuna | Kapadetan ayeuna | diaméterna | Beban ayeuna | Kapadetan ayeuna | ||

| Inci | mm | A | A/m2 | Inci | mm | A | A/m2 |

| 3 | 75 | 1000-1400 | 22-31 | 6 | 150 | 3000-4500 | 16-25 |

| 4 | 100 | 1500-2400 | 19-30 | 8 | 200 | 5000-6900 | 15-21 |

| 5 | 130 | 2200-3400 | 17-26 | 10 | 250 | 7000-10000 | 14-20 |

Bagan 3: Ukuran Éléktroda Grafit & Kasabaran Pikeun Éléktroda Grafit Diaméter Leutik

| Diaméterna nominal | Diaméter sabenerna (mm) | Panjang Nominal | Toleransi | |||

| Inci | mm | Max. | Min. | mm | Inci | mm |

| 3 | 75 | 77 | 74 | 1000 | 40 | -75~+50 |

| 4 | 100 | 102 | 99 | 1200 | 48 | -75~+50 |

| 6 | 150 | 154 | 151 | 1600 | 60 | ± 100 |

| 8 | 200 | 204 | 201 | 1600 | 60 | ± 100 |

| 9 | 225 | 230 | 226 | 1600/1800 | 60/72 | ± 100 |

| 10 | 250 | 256 | 252 | 1600/1800 | 60/72 | ± 100 |

Aplikasi Utama

- Peleburan kalsium karbida

- Produksi Carborundum

- Pemurnian korundum

- Lebur logam langka

- Ferrosilicon tutuwuhan refractory

Parentah Handing Jeung Ngagunakeun Pikeun Éléktroda Grafit

1.Use parabot ngangkat husus pikeun hirup éléktroda grafit ulah ruksak salila transportasi.(tingali pic1)

2.Graphite éléktroda kudu diteundeun jauh ti keur moistened atawa baseuh ku hujan, salju, dijaga garing.(tingali pic2)

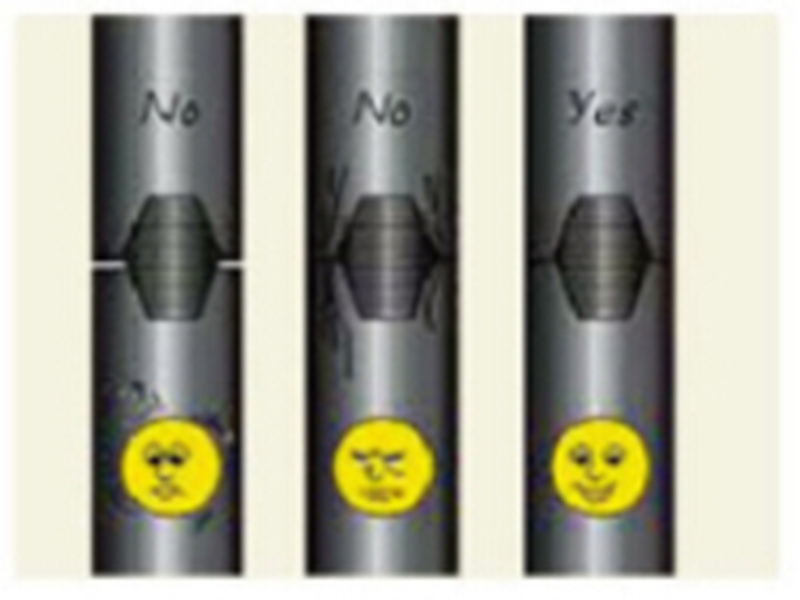

3. Carefully mariksa saméméh pamakéan mastikeun stop kontak na nipple thread téh cocog pikeun pamakéan, kaasup inspeksi pikeun pitch, colokan. (tingali pic3)

4.Bersihkeun nipple jeung sockets threads ku hawa dikomprés.(tingali pic4)

5.Before pamakéan, éléktroda grafit kudu garing dina tungku, suhu drying kedah kirang ti 150 ℃, waktos garing kedah leuwih ti 30hours. (tingali pic5)

6.Graphite éléktroda kudu disambungkeun pageuh tur straightly kalawan cocok tightening torsi.(tingali pic6)

7. Pikeun nyingkahan pegatna grafit éléktroda, nempatkeun bagian badag dina posisi handap sarta bagian leutik dina posisi luhur.